Brooke Mayer, associate professor of civil, construction and environmental engineering and head of the Mayer Research Group, is conducting research focused on new ways to purify water through Marquette University’s Water Quality Center.

The center is researching ways to deal with water quantity and quality issues. Mayer said part of her research focusing on water quality and treatment involves using visible light to disinfect bacteria.

“Light has energy associated with it and as you get it to a lower wavelength range, it has more energy and it starts to break bonds more efficiently and disinfect things,” Mayer said.

Mayer reviewed a Chinese group of researchers doing similar work in an article published on the website Nova. The researchers there are using energy from visible light to generate bacteria killing chemicals like hydrogen peroxide. Nova is the most watched prime time science television series on PBS.

“They are not the first team to do that, but they have the highest efficiency that has been reported yet,” Mayer said. “It’s a big advancement.”

Mayer said the Chinese researchers modified a metal-free semiconductor, graphitic carbon nitride — a chemical compound — to more efficiently move electrons around. She said it lessens the energy needed for the disinfection process.

“It’s a pretty cool trick where they’ve allowed those electrons to jump around, so that you can disinfect with just regular light instead of having to have really high-energy UV,” Mayer said. Rather than using UV light, which normally has more energy than visible light, the researchers manipulated the electrons to create higher energy.

Mayer said a lot of groups around the world are using metal as a semiconductor, but that could be counterproductive if toxins are released into the water while trying to disinfect it.

“This team has come in using a non-metal approach so that hopefully it’s safer and doesn’t release metals into the drinking water,” Mayer said.

Mayer said chlorine-based disinfection is the most common method used worldwide.

She said chlorine disinfectants are basically bleach. Mayer said when these disinfectants are added to water, they can react with other organic matter and can form disinfection byproducts that can cause harm to humans and the environment.

“Light-based disinfectants offer a nice alternative because they don’t have these byproducts,” Mayer said.

Mayer said chemical additions to disinfection processes can be more costly, depending on the scale and input.

“Using light is the most cost-effective means of disinfection right now,” Mayer said, adding that using UV light rather than visible light is the more expensive option.

Mayer said that because of its expensive nature, UV light disinfection is less widely used in the United States. She said, however, the use of light disinfection is increasing globally because developing countries and rural areas have readily access to visible light. Mayer also said these areas can make use of these disinfection processes because they cannot take advantage of wastewater treatment in municipalities.

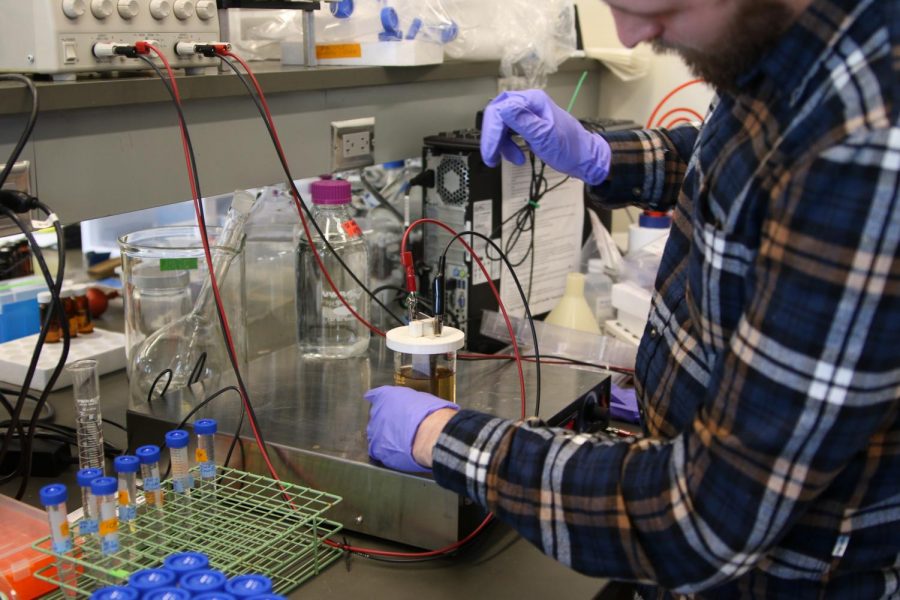

Donald Ryan, a graduate student in the College of Engineering and member of Mayer’s research team, said a lot of conventional UV research looks at how low and medium-pressure bulbs work as light sources.

“Our project slightly deviates from this,” Ryan said. “We used LED bulbs to provide the wavelength needed to clean water.”

Caitlin Graeber, a junior in the College of Engineering and member of Mayer’s research team, said the team used LED lights because they are more energy and cost efficient.

“Usually UV treatment is used with medium-pressure bulbs and we were trying to find a more sustainable way to use that,” Graeber said. “Now UV treatment is really expensive because it uses a lot of energy, so using the LED bulbs would make it more feasible and ideal for companies in our current water treatment plants to incorporate that kind of treatment process.”

Mayer said light-based disinfection has an appeal for locations such as developing nations and rural areas that do not have an advanced system already set up. She said with readily available access to visible light, a device could be set out in the sun to activate the disinfection process, which would supply consumable water.

“In most cases in the U.S. or a developed country setting, a multi-barrier approach is used,” Mayer said. “This involves a number of different treatment processes (involving) inputs and outputs that water passes through … with each process targeting a different broad class of contaminants.”

Mayer said this would make contaminants stick together so they are physically big enough to be removed from the system by gravity or a filter.

Mayer said another aspect of her research at Marquette involves resource recovery.

“Used water has lots of stuff that you don’t want to put back into the environment, but if you can get it out, some of it’s actually valuable,” Mayer said. “Phosphorus — like fossil fuels, like coal — is a nonrenewable resource, so there is a horizon of when we can’t get it out of the Earth effectively anymore.”

Mayer said her team is looking for ways to short cycle and extract phosphorous out of wastewater and reuse it as a soil additive, rather than using traditional fertilizer. Eileen Kennedy, a graduate student in the College of Engineering and member of Mayer’s research, said part of her research involves converting liquid, non-reactive phosphorus to solid, reactive phosphorus.

“One of Milwaukee’s highest pollutants is phosphorous, especially going into Lake Michigan,” Kennedy said.

According to the Wisconsin Department of Natural Resources, a quarter of the more than 700 Wisconsin waterbodies on the state’s impaired waters list have failed to meet water quality standards due to phosphorus pollution.

Kennedy said non-reactive phosphorus can be found in phytic acid, a preservative found in medical waste and food. She said phytic acid doesn’t get converted in wastewater treatment plants.

“A lot of the farmland that uses phosphorus in agriculture and in fertilizer all gets washed off into a stream,” Kennedy said.

According to the Wisconsin Department of Natural Resources, phosphorus enters lakes and streams after heavy rains and melting snow wash over farm fields and feedlots where fertilizer, manure and soil are present.

Kennedy said this non-point source runoff is difficult to address and control in comparison to point source runoff because the source of the runoff cannot be identified. She said point source runoff typically comes from wastewater treatment plants.

“I think that’s really where we can look at it,” Kennedy said, adding that the Wisconsin Department of Natural Resources limits the amount of phosphorus that can leave systems based on the total. The department also focuses on solid phosphorus rather than liquid.

Mayer said being on the cutting edge of research that can advance basic society needs is really exciting.

“We need that,” Mayer said. “We need to keep improving the systems that we have.”