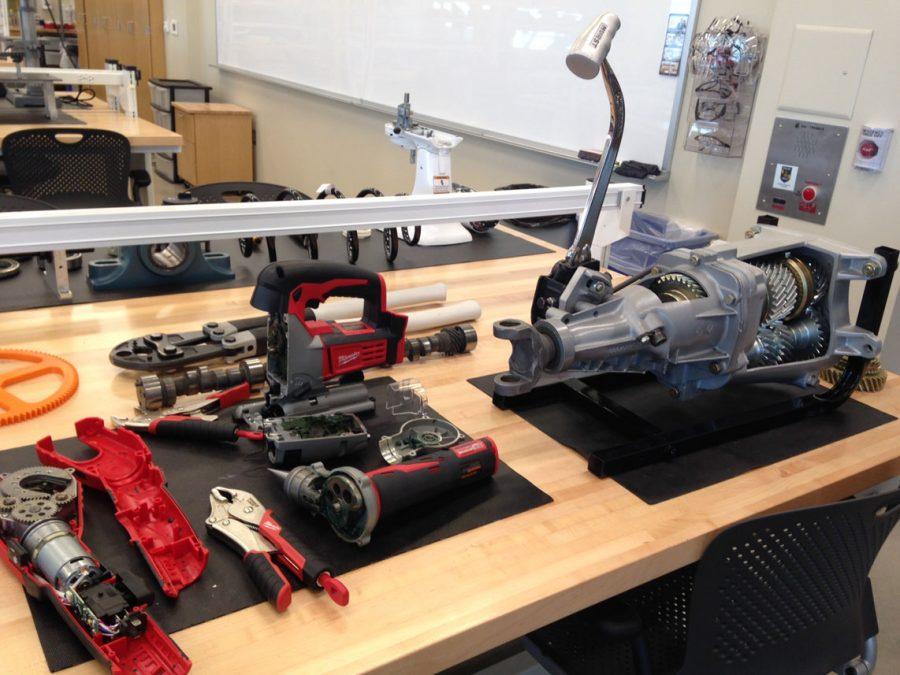

The Machine Design Lab in Engineering Hall received the invaluable donation of a 4-speed Chevrolet manual transmission from local Milwaukee company David’s 4 Speeds this August.

Dr. Mark Nagurka, an associate professor of mechanical engineering, gave details about the transmission.

“It was built specifically for us, kind of a 1970-era Chevrolet transmission,” Nagurka said. “It could’ve been a Camaro, but it was made for us so that it’s exposed and fully operable. It doesn’t have oil, you can see all the engagement of the teeth, you can set it in reverse, you can go through the speeds of the gears and see how the linkages of the gears work, and you can turn the shaft. It’s a valuable addition that I hope will be at Marquette for many years.”

Dominick Ropella, a junior in the College of Engineering who manages the day-to-day operations of the lab, described how the Machine Design Lab received the piece from David’s 4 Speeds owner Dave West.

“He is a really well-known vintage transmission rebuilder, so people have really nice old sports cars and he rebuilds their transmissions,” he said. “So what he did for us, specifically because we asked him, was he made a cutaway and plated all these gears really nice so we have a full working transmission.”

Ropella said that the piece is unique for the lab, making it indispensable.

“This will be a great piece for the future because this is something you can’t just buy off the shelf,” he said. “(West) made this specially for us. He actually had people from museums talking to him after this. They wanted a piece, and he said, ‘This isn’t something I just sell, this is a one-time thing for the lab.’ Pieces like this are just awesome.”

Engineering students use the lab for a Design of Machine Elements class. It is a required class for every mechanical engineering student.

Ryan Kaestner, a senior in the College of Engineering, plans to take the course next semester and is excited about more practical learning in the lab. “I can read things all day, but it takes hands-on experience to truly understand things,” Kaestner said.

Nagurka said he immediately realized the department needed industry guidance to create the lab. Nagurka worked with the department of engineering’s industrial advisory board to make the plan a reality.

“We held several evening meetings after work and people from Milwaukee Tool and a number of local companies came and we talked about what are the key attributes that they would want a graduating engineering student to know when they walk in the door as a hired engineer,” Nagurka said. “(The industry advisory board) helped me even in the planning of what activities and labs and experiments and experiences students should have. Because we were working with them, they were natural partners in donating things.”

The transmission is one of many pieces in the lab that gives students a firsthand learning experience, which Nagurka said is valuable for mechanical engineers.

“It’s a different modality of learning,” he said. “To really deeply learn, you have to experience. Although the authors of all the textbooks are also our teachers, conceptual learning and practical learning are very different…There’s a level of learning that is on the deepest psychological level of tactile sensation, of touching, and trying to understand by manipulating.”

Ropella said students are typically excited to work in the lab each week.

“This is a giant lab that makes learning fun,” he said. “We want students to come in here every week and we want them to be excited to learn about what they’re doing. Having actual stuff for them to play with keeps it fun, it keeps it exciting. They walk in here and think, ‘What can I pick up this week and play with?’ instead of, ‘What diagrams are we gonna look at this week?’”